Abstract

The evaluation of compaction in the field is a critical component to many construction processes. There are numerous technologies available to assess the in-situ1 density of soils including, but not limited to sand cone, balloon, nuclear density gauge, and others. Out of these, the sand cone is the simplest, and perhaps oldest, test method. All that is required is for a hole to be dug on the jobsite. This hole is then filled with sand of known density. By measuring the weight of sand required to fill the hole, the volume can be easily calculate using the sand density. Coupled with the known weight of soil that was removed from the hole at the time of digging, the density of the in-situ soil can be calculated.

Required Standards

The following specifications are required to complete this laboratory exercise:

ASTM D1556 – Standard Test Method for Density and Unit Weight of Soil in Place by Sand-Cone Method

Introduction

The sand cone test has been around for over 60 years. It is a reliable and straightforward method to measure unit weight in the field. This is an in-situ test method. While not a common test nowadays, as there are faster test methods available to determine the unit weight of a soil in the field, the sand cone remains a practical method that has no moving parts, batteries, or radioactive sources to maintain. Additionally, it is easy to see visually what is being measured.

Objectives

At the completion of this lab exercise, you will have satisfied the following objectives:

- Perform a calibration procedure for the sand cone equipment

- Perform a field unit weight measurement using the sand cone method

- Perform calculations necessary to determine the field unit weight

Learning Outcomes

At the completion of this lab exercise, you should be able to:

- understand an ASTM calibration process

- perform calculations necessary to determine the field unit weight from sand cone data

- understand the concept of compaction percentage

Procedure

The sand cone test procedure is divided into four parts: calibration, preparation, execution, and analysis. ASTM D1556 will be used for the calibration and procedure methods. Up to this point, we have largely ignored the calibration procedures in ASTM standards for our test methods. However, in the case of the sand cone test, it is extremely important and is done more often than with other testing procedures. The calibration will take place in the laboratory while the actual measurement will be conducted in the field.

Calibration

There are two steps to the calibration process but you will only be conducting the first step. The second step is described in ASTM D1556 Section A.2 and determines the unit weight of the sand used for the sand cone. This unit weight will be provided to you. You will generally follow the steps outlined in ASTM D1556 Section A.1. There are two methods listed but they are nearly identical. The second method simply outlines a procedure for multiple sand cone sets.

Following the procedures outlined for Method A in ASTM D1556 Section A1.2.3, you will set the base plate on the laboratory table and then weigh the sand cone apparatus. Then, place the sand cone in the base plate and open the valve and allow sand to fill the cone portion and the gap between the cone and table. After the sand stops flowing, you will close the valve and slowly remove the cone. You will then weigh the sand cone apparatus (which now has less sand in it). Finally, you will carefully scoop/sweep the sand into a container for reuse2. Using the provided unit weight of the sand, you can easily calculate the volume of the cone and gap by using the difference in weights. This value will be your cone correction factor.

Preparation

You will need five pieces of equipment for this procedure: sand cone apparatus (Fig. 1), base plate, scoop, sample container, and a scale3. Ensure the sand cone apparatus is filled with enough sand and obtain the filled weight of the apparatus. Finally, obtain the empty weight of the sample container.

Checklist

☐ Obtain sand cone apparatus and base plate

☐ Obtain scoop and sample container

☐ Obtain the filled weight of the apparatus

☐ Obtain the empty weight of the sample container

Execution

he execution process is straightforward. You will go to the designated site and set your base plate down. Hammer the soil stakes in to stabilize the base plate while you excavate the soil with the scoop. It is critical that as you scoop soil out to form a hole that you do not lose any soil. All of the excavated soil should be placed in the sample container and sealed until you can obtain the in-situ mass back in the lab.

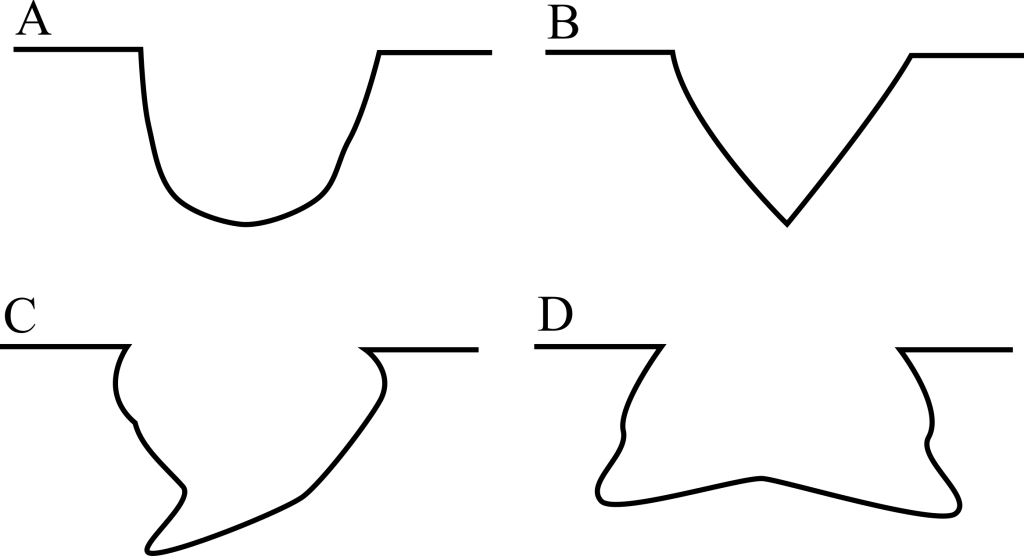

The minimum size of the hole is listed in ASTM D1556 Section 7.1.5 and is dependent on the gradation of the soil you are testing. Essentially, we want a hole big enough to reduce error but smaller than the volume of sand in our sand cone. The shape of the hole you dig is also important as we need the sand to freely flow and fill in the hole. We cannot have overhangs or crevices that the sand would not easily reach (Fig. 2).

After you have collected all of the loose soil in the sample container, seal it to prevent moisture loss while you complete the sand cone test. Place the sand cone apparatus on top of the base plate and ensure it is fully seated. Open the valve and allow the sand to fill the entire volume. Once the sand has stopped flowing, close the valve and slowly remove the sand cone apparatus. As previously mentioned, we generally cannot reuse the sand because it becomes contaminated with the soil we are testing on. Thus, you will leave the sand in the hole and remove the stakes and base plate for transport back to the lab.

Once back in the lab, obtain the weights of the soil sample and the emptied sand cone apparatus. Your soil sample will be oven dried and the resulting oven dry mass will be provided to you. Ensure your sample container is sufficiently labeled for later identification.

Checklist

☐ Excavate a hole and collect all soil in a sealed container

☐ Weigh sample container with moist soil sample

☐ Weigh emptied sand cone apparatus

☐ Place sample container in drying oven

Analysis

The calculations for determining the densities is straightforward and clearly outlined in ASTM D1556 Section 8. We first calculate the volume of the hole. This is done by taking the difference of the starting weight and ending weight of the sand cone apparatus, subtracting the calibration value determined earlier, and then dividing by the unit weight of the sand. Keep track of your units!

After the volume is known, the calculation of both wet and dry densities is easily performed. It is simply the measured wet or dry weight of the soil removed from the hole divided by the volume of the hole. The number of decimal places we can report to is outlined in ASTM D1556 Section 9.4.

The last thing we need to do with our data is to see at what “percent compaction” we were at in the field. When we run a density check in the field, we are trying to see if we have reached some target compaction. It is most commonly reported as a percentage of the maximum dry density, which was determined in the lab from the standard Proctor test following ASTM D698.

Example

For example, let’s assume our specimen has a maximum dry density, determined from the standard Proctor, of 125 lbs/ft\(^3\). If the results of our sand cone test determine that the in-situ dry density is 121 lbs/ft\(^3\), we have obtained 96.8% compaction. The required percentage depends on the project details, but minimum compaction values of 90% or 95% are most common.

Checklist

☐ Calculate the volume of the hole

☐ Measure dry mass of soil removed

☐ Calculate in-situ wet density

☐ Calculate in-situ dry density

☐ Calculate in-situ percent compaction

Summary

You have successfully run a sand cone test. As you likely noticed, the process is relatively straightforward and easy to run. This test used to be a routine test but was surpassed by faster and more accurate methods such as nuclear density gauges. Even though not as common, the sand cone method provides a good opportunity to visually observe how the compaction can be measured and more importantly, the size of the measurement.