Abstract

The hydrometer test indirectly characterizes the gradation of materials that are extremely small (i.e. particle size is less than 75 \(\mu\)m). In this method, the sample is blended in a high-shear mixer and then allowed to settle out over time. The change in density is measured over time and from Stokes Law, the particle sizes can be calculated.

Required Standards

ASTM D7928 – Standard Test Method for Particle-Size Distribution (Gradation) of Fine-Grained Soils Using the Sedimentation (Hydrometer) Analysis

ASTM E11 – Specification for Woven Wire Test Sieve Cloth and Test Sieves

The following specifications are optional, but they are listed here in the event more information is needed to complete the laboratory exercise:

ASTM D6026 – Standard Practice for Using Significant Digits in Geotechnical Data

ASTM E100 – Specification for ASTM Hydrometers

Introduction

The hydrometer testing procedure is an interesting procedure that indirectly measures the particle sizes of a soil sample that are smaller than the #200 sieve (75 \(\mu\)m). The keyword here is indirect measure. While it is possible to purchase sieves that have incredibly small openings, they are, as expected, incredibly expensive! Not to mention extremely fragile and easily clogged.

A hydrometer solves this issue as it is simple, requires no batteries, and maintains calibration relatively well (Fig. 1). When we place the hydrometer into a milkshake of soil sample, it will float to a certain level, due to the density of the solution. As the “milkshake” settles out, the density changes and the hydrometer slowly floats to a different level.

This is where Stokes’ Law comes into play. We first make several assumptions to use Stokes’ Law: smooth, perfectly round particles and the particles do not interact with one another. For certain soils, this assumption can be quite a bad one to make. But we do not have a much better option when it comes to the cost and ease of running the hydrometer test.

With those assumptions, Stokes’ Law is given by:

\[F_d=6\pi\mu R\nu\]

where:

\(F_d=\) friction force between particle and fluid

\(\mu=\) dynamic viscosity

\(R=\) radius of particle

\(\nu=\) velocity of fluid or particle

However, this equation is not useful for a hydrometer analysis. We are only measuring density changes! If we do some rearranging and most importantly, assume the particles are falling at their terminal velocity within the fluid, we get a more useful form of Stokes’ Law given by:

\[D=\sqrt{\frac{18\mu\nu}{ g\rho_f\left(\rho_p-1\right)}}\]

where:

\(D=\) diameter of particle1

The actual equation in ASTM D7928, as you will see when you perform the calculations, is slightly different than this form in that the particle velocity, \(\nu\), is calculated as the time it takes a particle to fall from an effective depth.

Objectives

At the completion of this lab exercise, you will have satisfied the following objectives:

- Perform a hydrometer test on a silty-clayey soil material

- Perform a hydrometer test on a sandy soil material

- Perform the calculations necessary to determine the gradation values smaller than the #200 (75 \(\mu\)m) sieve

- Construct a gradation chart of the two aforementioned materials over the complete range of particle sizes (i.e. combine the sieve analysis and hydrometer analysis)

Learning Outcomes

At the completion of this lab exercise, you should be able to:

- understand how Stokes’ Law is applied to soil gradation measurements

- perform calculations associated with hydrometer measurements to determine gradation values

- understand how to combine sieve analysis and hydrometer testing values to form a complete gradation of a soil material

- present information on gradations in a useful and professional manner

Procedure

The hydrometer testing procedure is divided into three parts: preparation, execution, and analysis. The testing procedure is relatively straightforward, however, unlike the sieve analysis procedure, it is easier to make measurement errors. If you brew your own beer or are picky with your engine coolant blend ratio, you may already be familiar with how to use a hydrometer and how difficult it can be to actually observe the reading on it.

This test is also extremely sensitive to temperature changes. Recall from the previous equations that there is a viscosity term, \(\mu\). This is an important consideration and the test method attempts to minimize the effects of temperature.

Preparation

We have two materials to be analyzed: a silty-clayey soil and a sandy soil. If we read ASTM D7928 Section 1.2, it states that clean sands cannot be effectively characterized with this method. We will see if our sandy soil has enough fines to be characterized with the hydrometer test method. The minimum sample weight we need is specified in ASTM D7928 Section 3.2.4 with the #10 (2 mm) sieve used as the separation sieve. It is important for you to note the hydrometer type (either 151H or 152H) as each one measures values in different units.

The sample itself is usually in some sort of moist condition. The hydrometers we will use can only “handle” a certain amount of soil in solution. It is also important to keep the sample sufficiently sealed as you prepare to execute the procedure2. So, if we are weighing a moist sample, the weight we record will be some amount of solids (i.e. the soil) and some amount of water. The 151H hydrometer can handle 45 g of solids and the 152H hydrometer can handle 55 g of solids. The ASTM D7928 specification provides an equation to estimate the amount of moist soil we can add to get close to the capacities of the hydrometers and is shown3 below:

\[M=H_c\times \left(\frac{100}{P_{200}}\right)\times \left(1+\left(\frac{w_c}{100}\right)\right)\]

where

\(M=\) mass of sample to weigh

\(H_c=\) capacity of hydrometer (i.e. 45 g or 55 g)

\(P_{200}=\) percent passing the #200 sieve, as a percent (i.e. 3.4%)

\(w_c=\) estimated moisture content, as a percent (i.e. 5.2%)

Weigh out an amount of moist soil that is close to the value calculated using the equation above. Then weigh out another amount of soil that is of similar weight. This second specimen will be oven-dried to determine the actual moisture content so that your later calculations can be performed.

The ASTM D7928 specification outlines procedures to check the calibration of the hydrometer. We will skip those procedures but be aware that these checks should be performed on a routine basis. Generally the hydrometer is sufficiently calibrated if it does not have any cracks or chips. Part of this calibration process determines the “effective depth” of the hydrometer. You will be provided this “effective depth” value.

Sometimes the soil material will flocculate, or clump together, when it is mixed in water. This can significantly affect the measurements and does not represent the true particle size distribution. The ASTM D7928 specification allows for the addition of a deflocculant: sodium hexametaphosphate. The use of this dispersant is based on general knowledge of the soil type being analyzed. Its use is not always required. For this laboratory, it is only used for the clayey-silty soil. The dispersant is added to the moist soil sample. Weigh out approximately 5 g of the sodium hexametaphosphate and record the exact amount that was added.

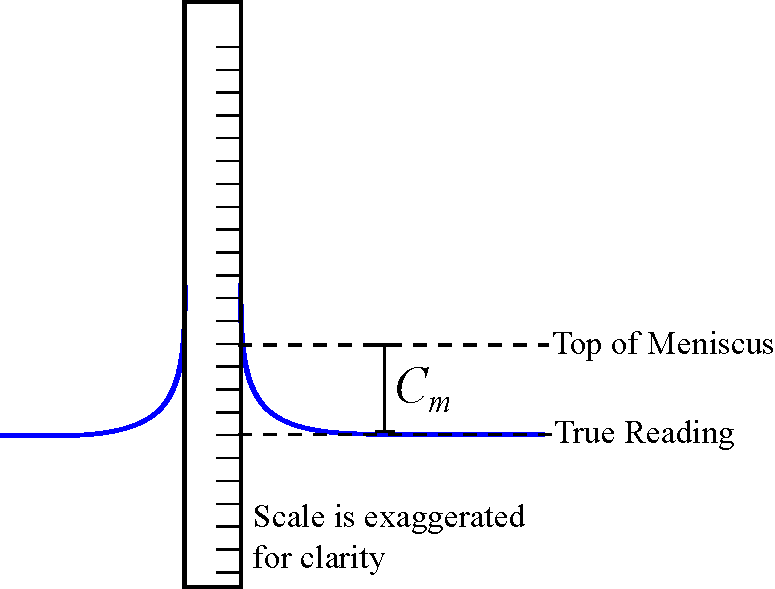

The final part of the preparation is to determine the meniscus correction factor for the hydrometer. Because the test procedure allows for varying amounts, or no amount, of a deflocculant, there is not a single meniscus correction factor that can always be used. It should be characterized each time the test is run and is relatively easy to determine. Recall from your basic chemistry courses that the meniscus is the curved part of water at the interface of a vertical surface. Most of the time, we read from the bottom of the meniscus however, during this test the water starts cloudy and it is usually impossible to read from the bottom of the meniscus. So we will read from the top of the meniscus and correct the measurement using a correction factor, \(C_m\). You will use the difference in height, in units of hydrometer markings, to correct your readings as shown in Fig. 2. Do your best to read to the nearest 1/4th division of the printed markings (Fig. 3).

Checklist

☐ Record the weight of the moist soil sample

☐ Record the weight of a second sample to oven dry for moisture content

☐ Record the weight of the deflocculant

☐ Determine and record the meniscus correction factor

Execution

The ASTM D7928 test procedure is relatively straightforward. The precise details are described in ASTM D7928 Section 11. For this laboratory exercise, we are using the referee stirring apparatus (i.e. milkshake-style blender) and referee agitator. The procedure involves an overnight rest period for the slurry to completely deflocculate. We will not employ the overnight conditioning period for this laboratory exercise.

The previously weighed sample is blended using a milkshake-style blender to homogenize and deflocculate the slurry. The blender cup should contain all of the weighed sample and enough of the test water, with or without the dispersant, depending on the sample, to fill the cup about halfway. The soil slurry should be blended for about 1 minute.

After blending, transfer the slurry to the sedimentation container. To get 100% of the slurry out of the blender cup, use a squirt bottle containing the test water, with or without the dispersant, depending on the sample, to rinse out the cup completely. Then fill the sedimentation container up to the 1000 mL line with the test water, with or without the dispersant, depending on the sample. You will then use the agitator to homogenize the slurry. You will start with the agitator near the bottom of the sedimentation container, using an smooth up and down motion. Watch the accompanying video to see this process more clearly. Agitate the solution for about 1 minute.

At this point, the slurry would normally be left to condition overnight. However, we will continue with the test procedure as described in ASTM D7928, resuming at Section 11.7.2. As soon as you remove the agitator from the sedimentation container, start a timer. Your first reading with the hydrometer will occur at the 1 minute mark, so ensure you have everything ready.

Approximately 20 seconds before the 1 minute mark, slowly guide the hydrometer into the soil solution. Be careful and do not allow the hydrometer to spin or bob. Ideally, you lower the hydrometer in the soil solution and when you notice it is neutrally buoyant, carefully release your grip. You want to have the hydrometer stabilized so that precisely at the 1 minute mark, you can take a reading. You will read the hydrometer from the top of the meniscus as described earlier.

Once you have obtained your reading, slowly and carefully remove the hydrometer. It should take you about 15 seconds to remove it from the soil solution. You are trying to minimize the disturbance of the solution and do not want to affect the particles from settling out. Once the hydrometer is removed, measure the temperature of the soil solution using the provided thermometer. The remaining times at which you must take a reading are listed in ASTM D7928 Section 11.8. Note that the next time is at 2 minutes from the point the agitator left the soil solution and no, you cannot leave the hydrometer in the soil sedimentation container to take that reading.

Each time you remove the hydrometer, you should rinse it off, dry it completely, and return it to the reference sedimentation container. This reference container only has water or water with the dispersant in it. The appendix4 of ASTM D7928 has two examples of data collection sheets that might be useful references for designing your own to record the experimental data. Namely, X1.1, X1.2, and X1.7 provide good references.

After the last reading, the slurry will be rinsed through a #200 sieve. The material retained on the #200 sieve will be oven dried and then weighed. This data will be provided to you.

Checklist

☐ Record the hydrometer reading at the specified times

☐ Record the soil solution temperature at the specified times

Analysis

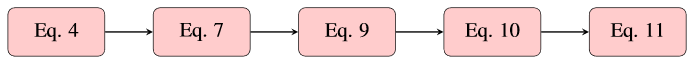

The analysis of the hydrometer data is more involved than the sieve analysis. The calculations are described in detail in ASTM D7928 Section 12. You should go step by step and create a spreadsheet to perform the calculations. To help you setup your spreadsheet, the following flowchart (Fig.4) describes the calculation process for each reading. After you setup your spreadsheet, it is recommended that you check your calculations with the two examples provided in the appendix (Fig. X1.1 and X1.2).

The second part is incorporating the hydrometer readings into your previous sieve analysis. If you notice, the hydrometer particle size analysis “starts” at the #200. It combines all the particles that are larger than 75 \(\mu\)m together. We cannot directly add the particle size distribution from the hydrometer to the end of the sieve analysis and call it a day. We must put the data in context of the entire gradation.

Example

The easiest way to explain this is to go through an example. A hydrometer dataset is shown in Table 1 below. Let’s also use the gradation shown in the fineness modulus example from Lab 2. There is 3% passing the #200 sieve. But wait, we have 56% finer as the first value in our hydrometer analysis! We need to normalize the hydrometer values to the amount that passed the #200 sieve in our sieve analysis. For instance, in the hydrometer analysis, we have 56% passing the 0.0450 mm size. In the context of the whole gradation, that is 56% of 3%, which is 1.68%. That means at the 0.0450 mm size, we have 1.68% passing in the context of the whole gradation. We continue the trend for all the measured particle sizes from the hydrometer analysis.

| \(D\), mm | Mass % Finer, \(N_m\) |

|---|---|

| 0.0450 | 56 |

| 0.0331 | 32 |

| 0.0261 | 21 |

| 0.0174 | 14 |

| 0.0120 | 11 |

| 0.0099 | 9 |

| 0.0071 | 5 |

| 0.0028 | 4 |

| 0.0013 | 3 |

Checklist

☐ Calculate particle sizes from hydrometer readings and associated mass percent finer values

☐ Incorporate the hydrometer values into the overall gradation data

Summary

We have successfully planned, executed, and analyzed the results of a hydrometer analysis on two different materials using ASTM D7928. This test procedures provides critical information about the clay and silt components of a soil and can allow us to make important design decisions. Although there are more accurate methods to determine small particle sizes, the hydrometer test method is straightforward, simple, and cheap.